WE CAST KNOWLEDGE AND DEDICATION

FUNDICIONES DEL ESTANDA (1953) is a modern steel foundry, which combines more than 70 years of casting experience and know-how with modern and highly automated manufacturing facilities and technology.

We supply all kinds of steel parts, both raw cast and machined, for use in diverse industrial sectors such as railways, cement, mining, commercial and heavy vehicles, machinery etc.

From our headquarters in beasain, gipuzkoa, we manufacture and supply all our customers in the various geographical markets. With a culture of customer focus and service, and a strong international vision, we are currently serving customers in more than 70 countries, based on the recognition and trust built up over relationships lasting many years.

We are strongly committed to sustainability and reduction of the carbon footprint of our organisation, through our specific ESTANDA GREEN STEEL plan.

Global presence

%

Annual sales in more than 70 countries worldwide, and 90% of exports

Experience and know-how

More than 425 in-house steel grades developed

Customers

More than 11,000 different models developed for customers

Production capacity

Installed capacity to supply >18.000 tonnes/year

PEOPLE, KNOW-HOW AND FOUNDRY TECHNOLOGY AT THE SERVICE OF YOUR BUSINESS

# TECHNICAL OFFICE,

MODELS AND PROTOTYPES

Simulation processes and internal analysis prior to casting parts. Design and manufacture of models. Manufacture of prototypes, and testing and approval processes.

# METALLURGY/

RANGE OF STEELS

More than 425 in-house formulations of steels tested in the field. Complete range of carbon, alloyed, refractory and stainless steels. Conformity with international material standards.

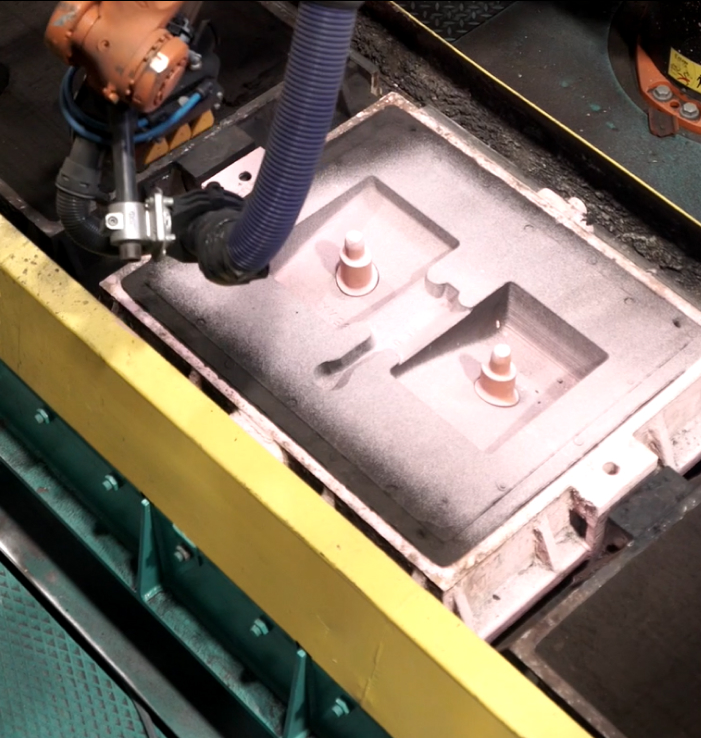

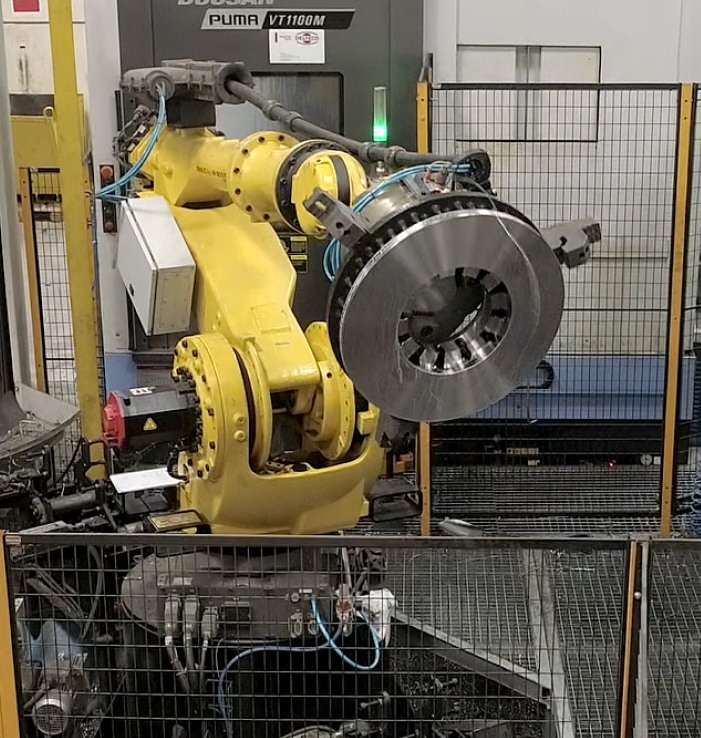

# MANUFACTURING

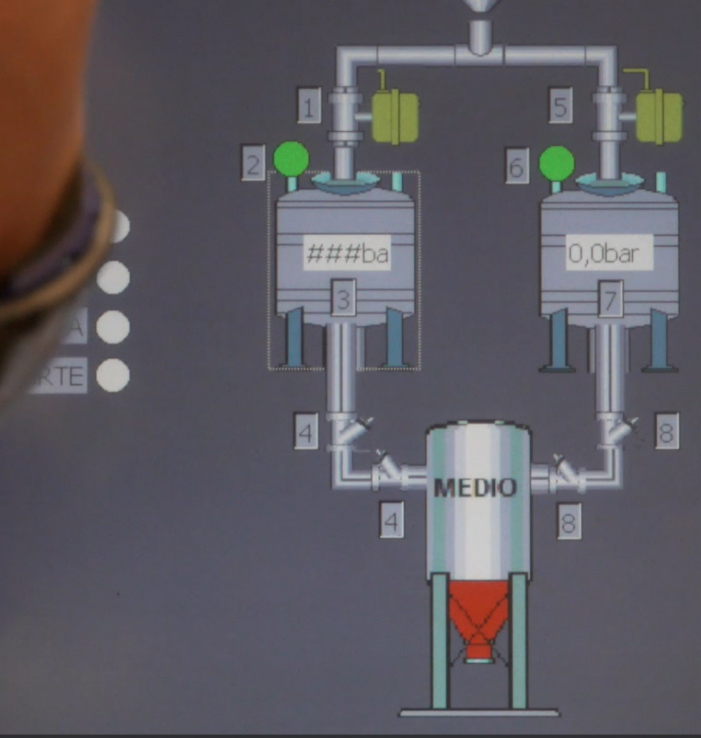

AUTOMATION

Automated manufacturing and control facilities and technology. Flexibility and reduction of delivery times. Full traceability of the production process.

# HEAT TREATMENT

In-house heat treatment facilities as a key part of our metallurgical process and know-how.

# MACHINING AND FINAL

CONTROL

Supply of raw cast parts and machined and finished parts. Welding, surface treatment and final inspection as required by the customer.

# EUROPEAN MANUFACTURE

We have 3 optimised production centres located in the north of Spain, from where we ship to all our customers in the various geographical markets.

# GLOBAL PRESENCEL

Sales in more than 70 countries. Our own sales network and network of agents in strategic markets. Close collaboration with customers over more than 25 years.

# SUSTAINABILITY

Strict and certified compliance with international management, environmental and occupational health and safety regulations. Carbon footprint reduction plan.

QUALITY AND SERVICE ARE TWO OF THE REASONS WHY SO MANY CUSTOMERS TRUST US.

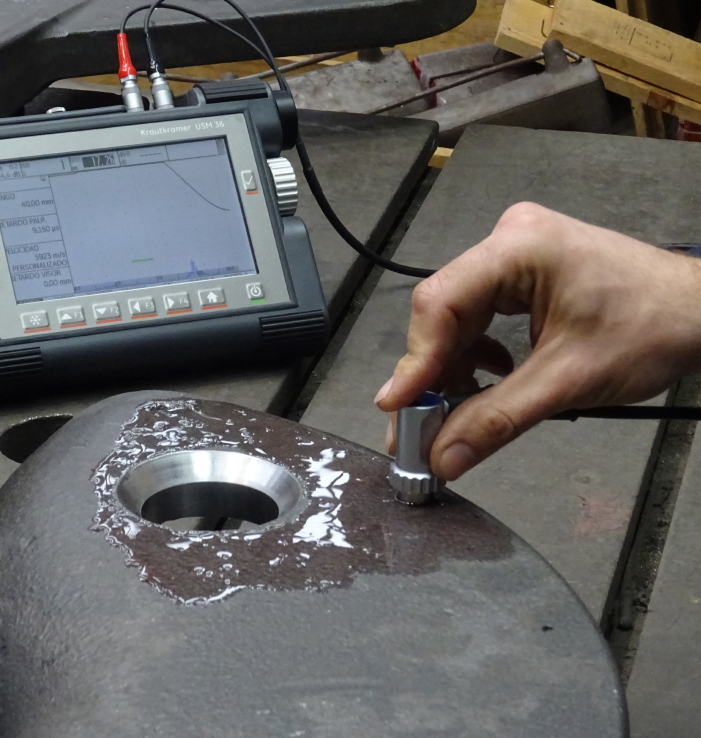

We control each and every stage of the manufacturing process, guaranteeing total traceability.

We draw up specific quality control plans for each customer and product.

We carry out all types of trials and tests, at prototype and series level: metallographic, mechanical, chemical composition, ultrasound, penetrating liquids, magnetic particles, radiographs, hardness, etc.

We have the following company and sector-specific certifications.

COMMITMENT, DEVELOPMENT AND SUSTAINABILITY

ESTANDA is a company committed to the economic development of its environment, of its environment, integrated into the society which it serves, collaborating in the creation of wealth and promoting new employment for future generations, and focussed on the sustainable development compatible with the preservation of the environment.

CO2 emission savings

0 kg CO2

*Accumulated savings in real time since 2022,

through the use of 100% renewable energy.

ESTANDA GREEN STEEL:

A SUSTAINABLE COMPANY

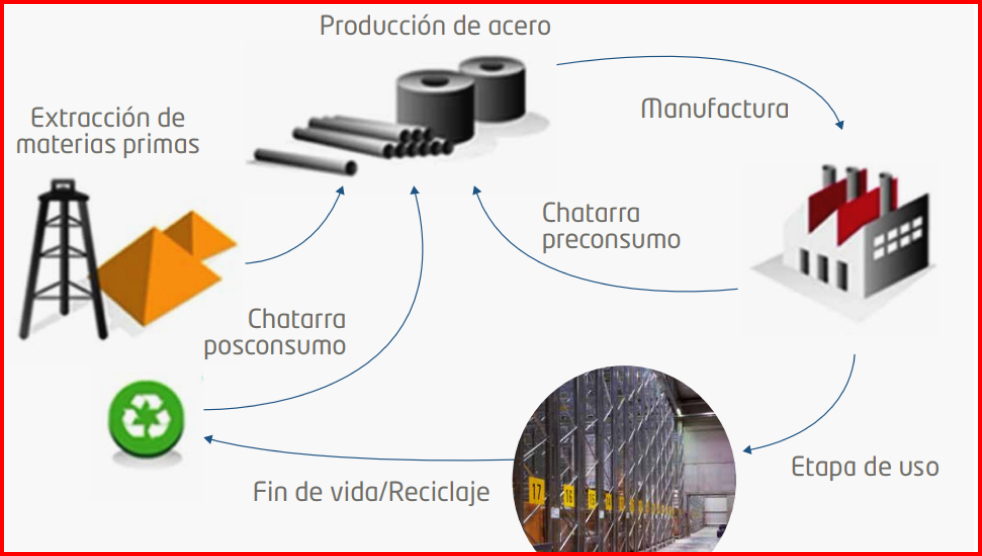

- Recycled raw materials: commitment to the use of 100% recycled steel scrap.

- Green energy: commitment to the use of 100% renewable energy in the casting and machining processes.

- Recycling of moulding sand and responsible waste management.

- Calculation of and targets for the organisation’s carbon footprint reduction (ghg protocol).

- Iso 14001 certified environmental management system.

- Iso 45001 occupational health and safety, social action, reconciliation of work and family life.

- Corporate social responsibility, relations with stakeholders and the local environment.

- Actions in support of the united nations sustainable development goals: specifically in chapters 3, 5, 6, 7, 8, 9, 12, and 13