GRINDING OF RAW AND

GRINDING OF CEMENT

Anti-wear steel parts for the interior of mills for raw and cement: Inlet headwall liners, Shell liners, Intermediate Diaphragms, Transfer Diaphragms, Central Discharge Diaphragms, and Outlet Diaphragms.

Wide selection of tested steels from which to choose according to the customer’s requirements and specific working conditions.

Manufacture of parts according to the customer’s current existing design and/or in-house design proposal for process optimisation.

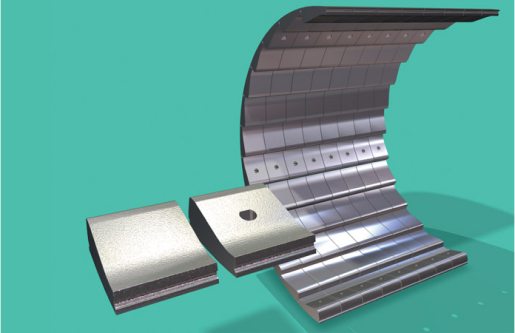

Feeding Systems

ESTANDA’s Feeding systems that regulate the inlet flow to the mills for raw and cement, improving ventilation and guaranteeing their optimal operation.

The installation of these feeding systems is simple, and they adapt to any type of mill.

These systems are characterised by::

- Step design to optimise mill ventilation.

- Steps removable for easy replacement and inspection of the mill, made of wear-resistant materials.

- Minimisation of leaks and losses of the material to be ground.

- Optimisation of transport capacity (worm/cone design).

- Expansion of the mill loading capacity (% filling).

Inlet Headwall liners

Design and supply of inlet headwall liners to reduce their wear and improve the capacity and regulation of the mill load:

- Increase in thickness or use of spoilers in the areas of maximum expected wear, also depending on the strength of the type of steel used.

- If the drilling allows it, subdivision by rings adapted to the areas of maximum wear of the inlet headwall liner.

- Adaptation of inlet headwall liners and inlet trunnion to increase the degree of filling, thereby obtaining greater productivity of the mill.

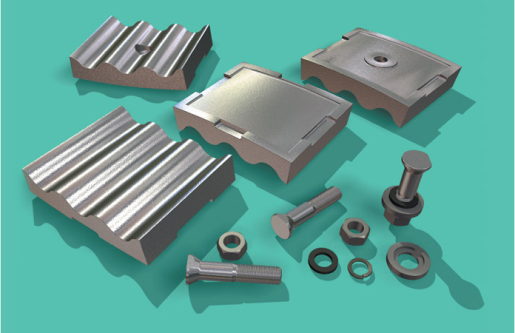

Lifting Liners

Lifting liners for the 1st chamber of horizontal mills.

Adapted to the 3 possible systems of fastening to the mill: bolted, semi-bolted and “vaulted” effect.

Option of different lifting profiles, and also option of different ranges of steel, for better resistance to wear due to impact as well as abrasion, according to the specific grinding conditions, always seeking to increase their useful life and optimise the grinding process.

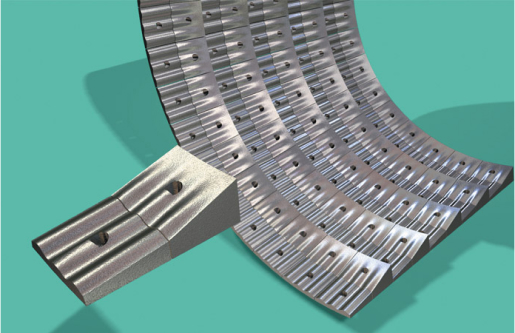

Classifying Liners

Classifying liners for the 2nd chamber of ball mills, designed to obtain a good classification of the grinding balls, optimal distribution of the material to be ground and avoiding overloads of the material.

Classifying profile in axial direction and with a slight lifting capacity in radial direction for optimum grinding performance.

Ball classification: homogeneous distribution of the grinding load according to size.

Choice of different ranges of steel with higher chrome contents from (13- 27%) for better abrasion resistance.

Wavy Liners

Wavy liners for mills with high degrees of filling, small balls and/or to increase the useful diameter of the mill.

Range of steels resistant to higher abrasive wear conditions, with high chrome contents (13- 27%).

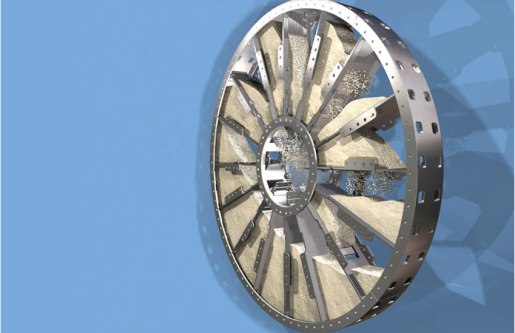

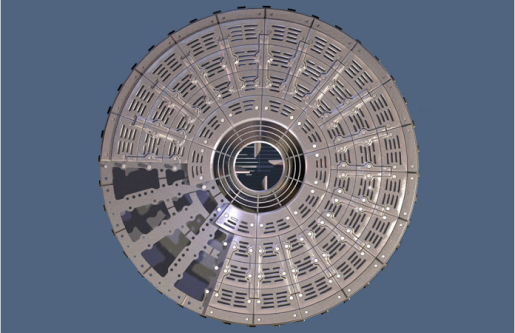

Improvest® Self-adjusting Intermediate Diaphragm

The ESTANDA Improvest® Self-regulating Intermediate Diaphragm is a diaphragm of our own patented design, with 30 years of successful operation and recognition in the market.

Main features:

- Intermediate diaphragm designed for optimum material flow between the 1st and 2nd chambers of cement ball mills.

- Easy adjustment: movable slide that can be adjusted according to the level of material in each chamber. Adjustment according to the conditions of the mill, by assigning alternate segments for material deposit and discharge in the diaphragm.

- Robustness, minimum maintenance: support structure in rolled carbon steels, and steels for the grids of both chambers with different chrome contents from (7 – 27%) depending on the grinding conditions.

- Specific flexible coupling system of the diaphragm to the shell, unaffected by the deformations of the mill shell.

- Design of diaphragm plates with maximum grid surface with minimum pressure loss of ventilation air.

- Self-regulation system with patented equipment that guarantees a constant level in both chambers, eliminating inefficient areas and obtaining maximum efficiency and energy optimisation.

- Pre-assembly in ESTANDA: guarantee of perfect assembly.

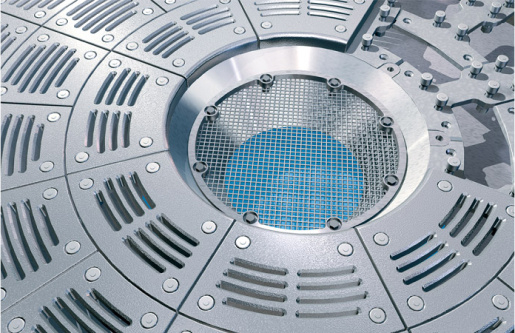

Central Discharge Diaphragm

Diaphragm designed for use in Bi-rotator Type Raw Mills, to retain the balls and sizes of the material to be ground above the slots of the grids, facilitating the central discharge of the ground material.

The grids are manufactured with maximum slotted surfaces, balancing their safety and durability with minimum pressure loss of the air blown through them.

The plates of the grids are manufactured from low and medium chrome content (7 – 13%) anti-wear steels, selected according to the grinding conditions.

Transfer Diaphragm

Diaphragm designed for use in Raw Mills, between the drying chamber and the 1st chamber. They are also often referred to as ‘drying diaphragms’.

The wet material enters the mill together with the stream of hot gases. The transfer or standard drying diaphragm optimises the heat transfer between the material and the gases, allowing the discharge of the dry material through the central ring into the 1st chamber by means of anti-wear cogs.

The grids in the 1st chamber are designed to allow the material and hot gases to pass through with a minimum pressure drop. The cast materials for these grids are chosen according to the working conditions (resistance to oxidation, thermal shock, abrasion, etc.).

Finally, the central screen is designed to prevent the passage of balls into the drying chamber.

Outlet Diaphragm

Diaphragm for use in horizontal mills.

The ESTANDA outlet diaphragms are designed to retain the grinding elements (balls, cylpebs, etc.), ensuring the ideal level of material in the last chamber.

The structure is attached to the outlet wall.

The cogs on the inside of the diaphragm allow the material to be discharged correctly.

The design of the grids ensures a minimum loss of air pressure in the diaphragm, as well as a correct discharge of the material.