MINING

In the MINING sector ESTANDA offers a wide range of steels and specific alloys for the breaking, crushing and grinding processes of rocks and minerals.

Steels resistant to wear from impact and abrasion:

- High chrome steels (white cast iron)

- Chrome Molybdenum steels: pearlitic and martensitic

- Manganese steels

- Refractory steels resistant to high temperature

Most frequent type of applications:

- CRUSHING processes

- GRINDING processes

01

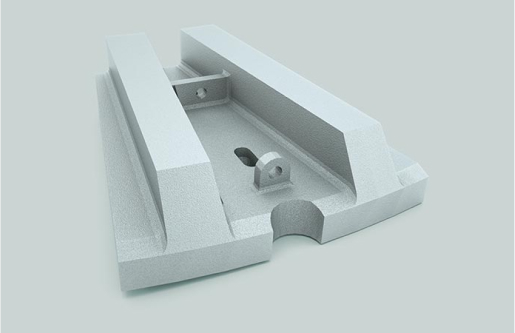

CRUSHING

Wear parts such as Hammers, Bars, Jaws, Impact Plates, etc. For the different crushing equipment.

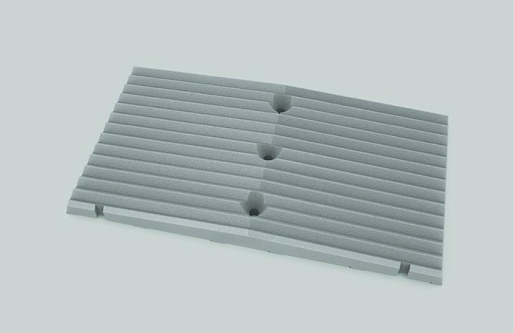

02

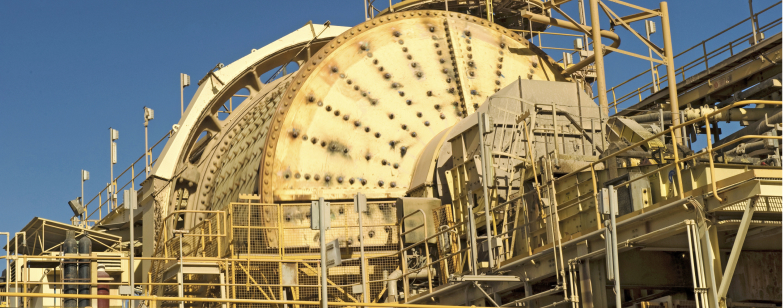

GRINDING

Inlet Headwall Liners, Liners, and Outlet Diaphragms for all types of mills used in mineral processing..